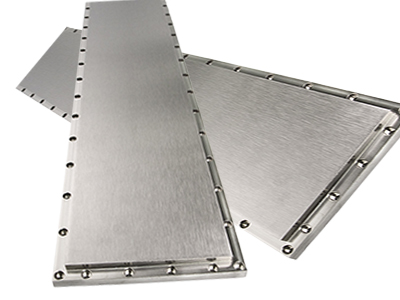

Titanium Plate Target

Titanium Target: Wy brûke titanium alloy billet, of plaat te machined yn titanium targets.The ûnreinens ynhâld fan yndustrieel suver titanium is mear as dy fan gemysk suver titanium, dus syn sterkte en hurdens binne wat heger.De meganyske en gemyske eigenskippen binne fergelykber mei dy fan roestfrij stiel.Yn ferliking mei titanium alloy, suver titanium hat bettere sterkte en hat bettere oksidaasje ferset.It is better as austenitic RVS, mar syn waarmte ferset is min.TA1, TA2, TA3 ferheging fan ûnreinheden ynhâld, meganyske sterkte en hurdens tanimme yn oarder, mar plastic taaiens nimt ôf yn oarder.

• Tittanium Plate Target: Grade1, Grade 2, Grade 5, Grade 5, Grade7, Grade9, Grade11, Grade12, Grade 16, Grade23 ect

• Soarten:Round Target, Pipe Target, Plate Target.ect

• Diminsje:60/80/120(W)×6/8/12(T)×519/525/620(L) &60-800(W)×6-40(T)×600-2000(L)Oanpast

•Soerflak:helder oerflak of Acid pickling oerflak

• Oanfraach: brûkt yn semiconductor skieding apparaten, flat-paniel byldskermen, opslach elektrodes films, sputtering coating, workpiece oerflak coating, glêzen coating yndustry, ensfh

| Titanium Alloys Materiaal Common Name | ||

| Gr1 | UNS R50250 | CP-Ti |

| Gr2 | UNS R50400 | CP-Ti |

| Gr4 | UNS R50700 | CP-Ti |

| gr7 | UNS R52400 | Ti-0.20Pd |

| G9 | UNS R56320 | Ti-3AL-2.5V |

| G11 | UNS R52250 | Ti-0.15Pd |

| G12 | UNS R53400 | Ti-0.3Mo-0.8Ni |

| G16 | UNS R52402 | Ti-0.05Pd |

| G23 | UNS R56407 | Ti-6Al-4V ELI |

♦ Titanium Alloys Chemical Composition ♦

| Klasse | Gemyske gearstalling, gewicht persintaazje (%) | ||||||||||||

| C (≤) | O (≤) | N (≤) | H (≤) | Fe (≤) | Al | V | Pd | Ru | Ni | Mo | Oare eleminten Max.elk | Oare eleminten Max.totaal | |

| Gr1 | 0.08 | 0.18 | 0.03 | 0.015 | 0.20 | - | - | - | - | - | - | 0.1 | 0.4 |

| Gr2 | 0.08 | 0.25 | 0.03 | 0.015 | 0.30 | - | - | - | - | - | - | 0.1 | 0.4 |

| Gr4 | 0.08 | 0.25 | 0.03 | 0.015 | 0.30 | - | - | - | - | - | - | 0.1 | 0.4 |

| Gr5 | 0.08 | 0.20 | 0.05 | 0.015 | 0.40 | 5.56.75 | 3.5 4.5 | - | - | - | - | 0.1 | 0.4 |

| gr7 | 0.08 | 0.25 | 0.03 | 0.015 | 0.30 | - | - | 0.12 0.25 | - | 0.12 0.25 | - | 0.1 | 0.4 |

| gr9 | 0.08 | 0.15 | 0.03 | 0.015 | 0.25 | 2.5 3.5 | 2.0 3.0 | - | - | - | - | 0.1 | 0.4 |

| Gr11 | 0.08 | 0.18 | 0.03 | 0.15 | 0.2 | - | - | 0.12 0.25 | - | - | - | 0.1 | 0.4 |

| Gr12 | 0.08 | 0.25 | 0.03 | 0.15 | 0.3 | - | - | - | - | 0,6 0,9 | 0,2 0,4 | 0.1 | 0.4 |

| Gr16 | 0.08 | 0.25 | 0.03 | 0.15 | 0.3 | - | - | 0.04 0.08 | - | - | - | 0.1 | 0.4 |

| Gr23 | 0.08 | 0.13 | 0.03 | 0.125 | 0.25 | 5,5 6,5 | 3.5 4.5 | - | - | - | - | 0.1 | 0.1 |

♦Titanum AlloyFysike Eigenskippen ♦

| Klasse | Fysike eigenskippen | |||||

| Treksterkte Min | Yield sterkte Min (0.2%, offset) | Ferlinging yn 4D Min (%) | Reduksje fan Area Min (%) | |||

| ksi | MPa | ksi | MPa | |||

| Gr1 | 35 | 240 | 20 | 138 | 24 | 30 |

| Gr2 | 50 | 345 | 40 | 275 | 20 | 30 |

| Gr4 | 80 | 550 | 70 | 483 | 15 | 25 |

| Gr5 | 130 | 895 | 120 | 828 | 10 | 25 |

| gr7 | 50 | 345 | 40 | 275 | 20 | 30 |

| gr9 | 90 | 620 | 70 | 483 | 15 | 25 |

| Gr11 | 35 | 240 | 20 | 138 | 24 | 30 |

| Gr12 | 70 | 483 | 50 | 345 | 18 | 25 |

| Gr16 | 50 | 345 | 40 | 275 | 20 | 30 |

| Gr23 | 120 | 828 | 110 | 759 | 10 | 15 |